1.Summary of ZJHM Pneumatic Sleeve Regulating Valve:

ZJHM pneumatic sleeve control valve is composed of multi-spring pneumatic film actuator and straight-through low flow resistance balanced sleeve valve. It has compact structure, light weight, sensitive movement, S-streamline fluid channel, small pressure drop loss, large valve capacity, accurate flow characteristics, power-pneumatic valve positioning or pneumatic valve positioner, which can realize the process pipeline. The automatic control of fluid medium is widely used to precisely control the process parameters of gas, liquid and steam, such as pressure, flow rate, temperature, liquid level, etc. to keep the given values. It is a new generation of universal control valve products in line with IEC standards.

2. Structural characteristics of ZJHM type pneumatic sleeve control valve:

1. Pneumatic sleeve regulating valve is the actuating unit of instrument in automation control system. It adopts electric-pneumatic valve positioner, uses electric signal and compressed air as driving force, receives 0-10mA DC or 4-20mA DC current signal input from control system, and converts compressed air into air source pressure signal input and output by regulator, which can realize split-range control.( By changing the opening displacement of the valve, the precise adjustment and control of the technological parameters of the fluid medium can be achieved.

2. Pneumatic sleeve control valve can be divided according to the mode of action; Positive effect: pneumatic closed-normal open type (valve position downward displacement when signal pressure increases), "B type"

Reaction: Air Open - Normally Closed (Valve Position Displacement Up When Signal Pressure Increases), "K" Type

3. The pneumatic sleeve control valve adopts balanced spool, which has small unbalance force and stable operation. It is suitable for working occasions where the pressure difference between the front and back of the valve is large and the leakage is slightly larger.

4. The through low flow resistance sleeve valve core adopts the pressure balanced valve core structure (double sealing surface or single sealing surface). The valve core is cylindrical. After precise processing, it opens a window with certain characteristics, which is guided by the inner circle of the sleeve and the top. Therefore, the unbalanced force on the valve stem is very small, the operation is stable and the performance is good. It is a force balanced regulating valve. When the pressure difference between the front and back of the valve is high, the vibration caused by the eddy current impact is weakened due to the side guide of the sleeve. Therefore, the valve has the advantages of low noise, small cavitation flash and long service life. However, the leakage rate of the valve seat is slightly larger than that of the single seat valve.

5. By changing the design of the shape of the valve core, different flow characteristics can be obtained with different shape of the valve core window: equal percentage (logarithmic) and linearity.

This series of products are widely used in automatic regulation and remote control of industrial processes such as chemical industry, petroleum, metallurgy, power station, light textile, paper making and pharmaceuticals.

There are standard type, adjustable cut-off type, bellows sealed type, jacket insulation type and other varieties. The product pressure level has PN1.64.06.4 MPa; nominal diameter DN20-300 mm; applicable fluid temperature is - 60-450 C; according to the temperature, different valve caps can be divided into normal temperature type, high temperature type and low temperature type.

3.Main technical parameters of executing agencies:

型 号 | ZHA-22 | ZHA-23 | ZHB-34 | ZHA-45 | ZHA-56 |

有效面积cm2 | 350 | 350 | 560 | 900 | 1600 |

行 程mm | 16 | 25 | 40 | 60 | 100 |

弹簧范围KPa | 20∼100(标准):40∼200;80∼240; 20∼60; 60∼100 | ||||

操作方式 | 普通型,带手动手轮操作型(侧装式,顶装式) | ||||

4.Performance Indicators of ZJHM Pneumatic Sleeve Regulating Valve:

项目 | 指标值 | 项目 | 指标值 | ||||

基本误差% | 不带定位器 | ±5.0 | 始 | 气关 | 不带定位器 | 始点 | ±5.0 |

带定位器 | ±1.0 | 终点 | ±2.5 | ||||

回差% | 不带定位器 | ≤3.0 | 带定位器 | 始点 | ±1.0 | ||

终点 | ±1.0 | ||||||

带定位器 | ≤1.0 | 气开 | 不带定位器 | 始点 | ±2.5 | ||

终点 | ±5.0 | ||||||

死区% | 不带定位器 | ≤3.0 | 带定位器 | 始点 | ±1.0 | ||

终点 | ±1.0 | ||||||

带定位器 | ≤0.4 | 允许泄漏量L/h | 1×10-3×阀额定容量 | ||||

额定行程偏差% | ±2.5 | ||||||

注:本产品执行GB/T4213-92国家标准.

5.Main parts and materials of ZJHM type pneumatic sleeve control valve:

材料代号 | C(WCB) | P(304) | R(316) | |

主要 零件 | 阀体,阀盖 | WCB(ZG230-450) | ZG1Cr18Ni9Ti(304) | ZG1Cr18Ni12Mo2Ti(304) |

阀芯,阀座 | 1Cr18Ni9Ti(304)或司钛莱合金堆焊 | 1Cr18Ni9Ti(304)或司钛莱合金堆焊 | 1Cr18Ni12Mo2Ti或司钛莱合金堆焊 | |

阀杆 | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | |

填料 | V型聚四氟乙烯,柔性石墨,不锈钢波纹管 | |||

垫片 | 增强聚四氟乙烯 ,不锈钢垫片,金属石墨缠绕垫片 | |||

上下膜盖 | A3钢板冲压 | |||

波纺膜片 | 丁晴橡胶夹增强涤沦织物 | |||

弹簧 | 60Si2Mn | |||

推杆,衬套 | 2Cr13 | |||

轴套 | 聚氨酯(用于反作用) | |||

适用 工况 | 适用介质 | 水蒸汽油品类气液体 | 硝酸碱类腐蚀性气液体 | 醋酸类等腐蚀性气液体 |

常温型 | -30∼+250 F4:≤200℃ | -40∼+250 F4:≤200℃ | -40∼+250℃ F4:≤200℃ | |

高温型 | -30∼+450℃ | -40∼+550℃ | -40∼+550℃ | |

低温型 | -40∼-60℃, -60∼-100℃ | |||

6.Main technical parameters of JHM type pneumatic sleeve control valve:

公称通径mm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

阀座直径mm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

额定流量 | 直线 | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 | 1100 | 1760 |

等百分比 | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 | 1000 | 1600 | |

额定行程L(mm) | 10 | 16 | 25 | 40 | 60 | 100 | ||||||||

执行器型号 | ZHA/B-22 | ZHA/B-22 | ZHA/B-23 | ZHA/B-34 | ZHA/B-45 | ZHA/B-56 | ||||||||

薄膜有效面积Ae(cm2) | 350 | 350 | 350 | 560 | 900 | 1600 | ||||||||

气源压力Ps(MPa) | 0.14∼0.4 | |||||||||||||

信号范围Pr(KPa) | 20∼100,40∼200,80∼240 段幅:20∼60,60∼100 | |||||||||||||

电信号 | 4∼20mA DC或0∼10mA DC | |||||||||||||

作用模式 | 气开式(K)型,气关式(B)型 | |||||||||||||

流量特性 | 直线,等百分比,快开性 | |||||||||||||

允许泄漏量(L/h) | 硬密封:1×10-3×阀额定容量 | |||||||||||||

固有可调比R | 50:1 | |||||||||||||

气源接头 | M16×1.5 | |||||||||||||

公称压力PN(MPa) | 1.6 2.5 4.0 6.4 | |||||||||||||

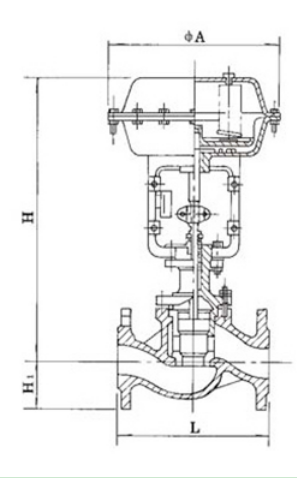

7.Main Outline Dimensions of ZJHM Pneumatic Sleeve Regulating Valve:

公称通径(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||

L(mm) | PN1.6MPa | 181 | 184 | 205 | 222 | 254 | 276 | 298 | 352 | 410 | 451 | 600 | 670 | 735 | |

PN4.0MPa | 194 | 200 | 210 | 235 | 267 | 292 | 317 | 368 | 425 | 473 | 615 | 685 | 750 | ||

PN6.4MPa | 205 | 210 | 220 | 251 | 286 | 311 | 337 | 394 | 440 | 508 | 650 | 700 | 765 | ||

H1(mm) | PN1.6MPa | 53 | 58 | 68 | 73 | 80 | 90 | 98 | 108 | 123 | 140 | 168 | 203 | 230 | |

H1(mm) | PN4.0MPa | 53 | 58 | 68 | 73 | 80 | 90 | 98 | 115 | 135 | 150 | 188 | 223 | 255 | |

H1(mm) | PN6.4MPa | 63 | 68 | 75 | 83 | 88 | 100 | 105 | 125 | 148 | 170 | 203 | 235 | 265 | |

H(mm)≈ | 常温型 | 398 | 410 | 454 | 457 | 460 | 610 | 622 | 640 | 846 | 870 | 890 | 1203 | 1234 | |

高温型 | 548 | 560 | 604 | 520 | 627 | 790 | 807 | 850 | 1096 | 1130 | 1150 | 1523 | 1554 | ||

低温型 | -100℃ | H2 | 500 | 600 | 700 | ||||||||||

H≈ | 926 | 935 | 974 | 1082 | 1090 | 1240 | 1252 | 1275 | 1596 | 1620 | 1640 | ||||

ΦA(mm) | 285 | 360 | 470 | 620 | |||||||||||

VIII: Quotation Notes:

1. Valve body parameters: caliber, working pressure, valve body material, use of media, temperature, connection form and other parameters.

2. Actuator: Actuator form, control mode, control signal (4-20MA), mode of action (gas-open, gas-close)

3. If the type of control valve has been selected by the design unit, please report the type of throttle valve directly to our sales department for order.

4. If you need customization, you can contact us. Welcome to call: 021-66400088.

Please provide as detailed as possible about the parameters of the throttle valve, so as to facilitate our technicians to select the type accurately for you. If you have any questions, please call us 021-66400088. We will do our best to provide you with the best service.