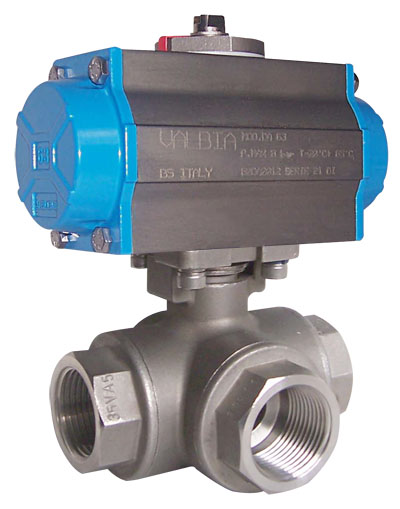

Pneumatic ball valves are available in O-ball valves and V-ball valves. O-type ball valve adopts floating structure, the core is precision casting, the surface is hard chrome-plated, the valve seat is made of reinforced polytetrafluoroethylene data, the flow port is the same as the pipe diameter, the flow can be large, the flow resistance is very small, and there is no leakage when closed. It is generally used as an on-off valve. It is especially suitable for high-viscosity, V-type ball valves with a fixed structure. The V-shaped slit is opened on the core to cut the fiber-containing and granular media.

1. According to different process equipment, pneumatic or electric actuators can be selected to form pneumatic ball valve and electric ball valve respectively. In order to complete the share adjustment, the pneumatic ball valve must be equipped with a valve positioner. If the electric ball valve needs to complete the share conditioning, the electronic electric actuator must be selected. Or with a servo amplifier, etc.

2. From the material, can be divided into: carbon steel ball valve, stainless steel 304 ball valve, 316 ball valve and copper ball valve

3. According to the pressure, can be divided into: high pressure ball valve and low pressure ball valve

High-pressure pneumatic ball valve: The primary application in oil, natural gas, hydraulic oil, construction machinery and other industries

Low-pressure pneumatic ball valve: The primary application is in corrosive pipelines such as water! Precautions and models of knife-type gate valve application: The opening and closing part of the knife-type gate valve is the gate. The direction of movement of the gate is straight with the direction of the fluid. The manual knife-type gate valve can only be fully open and fully closed. And throttling. The gate has two sealing faces. The two sealing faces of the common mode gate valve form a wedge shape, and the wedge angle varies with the valve parameters, generally 50. The gate of the wedge knife gate valve can be made into a whole body, called rigidity. The ram can also be made into a ram that can produce a small amount of deformation to improve its processability and compensate for the error caused by the sealing surface of the sealing surface. When the ram is called a flexible ram-type gate valve, the sealing surface can be closed. Only rely on the medium pressure to seal, that is, relying on the medium pressure to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing. Most knife-type gate valves use forced sealing, that is, valves When closing, it is necessary to force the ram to press against the valve seat according to external force to ensure the sealing of the sealing surface. This type of valve should generally be horizontally installed in the pipeline.

Shanghai Gaocheng Valve Manufacturing Co., Ltd. is a pneumatic ball valve brand enterprise integrating scientific research, design, manufacture, sales and service. It has accumulated rich production and sales experience in the field of industrial automation valves.

We will continue to apply new technologies, new processes, new materials to actively develop more cost-effective products, and provide strong protection for users and partners with a warm attitude and thoughtful service. Strive to be an excellent supplier of valve products! Welcome to contact us: 18917790199